Tank Audits and Decommissioning: A Structured, Compliant Approach

Fuel, leachate, and process tanks are long-life assets, but they are not permanent ones. When tanks reach the end of their operational life, or when sites change use, expand, or modernise, they require a structured audit and decommissioning plan.

How OTS Group approaches tank audits & decommissioning

At OTS Group, tank audits and decommissioning projects are treated as safety-critical, environmentally sensitive engineering exercises. The objective is not simply to remove a tank, but to do so in a way that manages risk, maintains compliance, and allows the site to move forward without disruption or legacy issues.

This article outlines our 5-step process to carrying out tank audits and translating findings into safe, compliant decommissioning strategies.

Stage 1: Audit planning and data review

Before stepping on site, OTS engineers review all available information to understand the asset and its operational history.

This typically includes:

Tank drawings and specifications

Age, capacity, and construction type

Fuel or product type stored

Previous service, inspection, or maintenance records

Known site constraints or operational considerations

Alongside this, the relevant regulatory and safety frameworks are identified. These may include environmental regulations, fire safety guidance, confined space requirements, and local authority conditions.

The output of this stage is a defined audit methodology and inspection checklist, tailored to the specific tanks and site conditions, rather than a generic inspection approach.

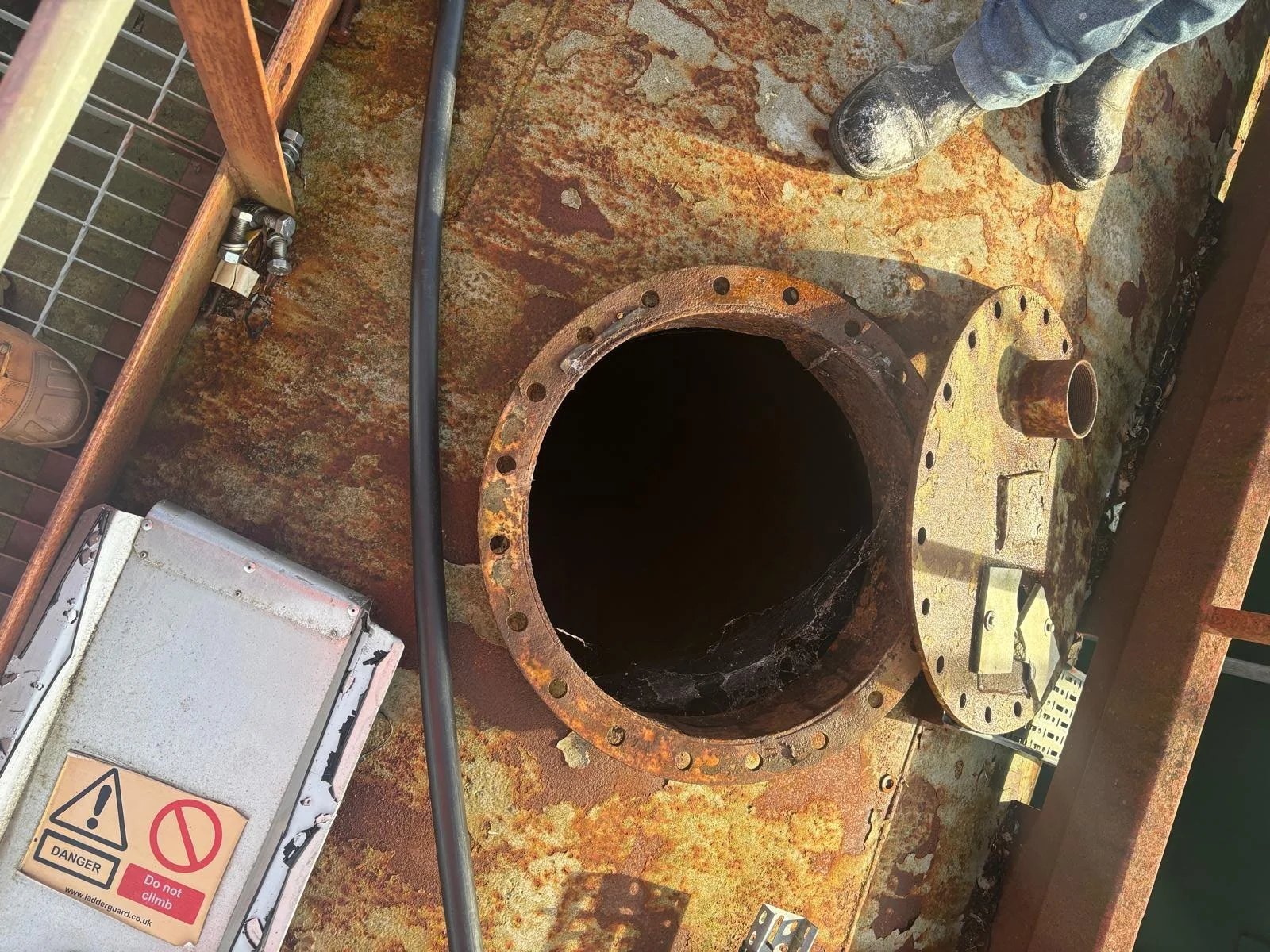

Stage 2: On-site tank inspection

The site audit focuses on the physical condition of the tank and its surrounding infrastructure.

During the inspection, OTS engineers assess:

Tank structure, shell condition, and corrosion

Bund integrity and secondary containment

Pipework, valves, vents, and fittings

Identification, labelling, and accessibility

Walkways, ladders, and access systems

Surrounding ground conditions and environmental exposure

This stage is as much about context as condition. A structurally sound tank may still present risk if access is unsafe, pipework is poorly configured, or if surrounding ground conditions raise contamination concerns.

Stage 3: Fuel and residual assessment

Understanding what remains inside a tank is a critical part of the audit.

We confirm:

Whether the tank contains usable fuel, waste product, sludge, or vapour

The volume of residual material present

Signs of contamination, water ingress, or degradation

The presence of hazardous materials, including fuel vapours or legacy coatings

This assessment informs the next stages of planning. A tank with minimal clean fuel may be treated very differently to one containing contaminated product or heavy sludge.

Stage 4: Environmental and safety risk assessment

Tank decommissioning carries inherent risks, particularly when fuel or leachate systems are involved. OTS carries out a detailed environmental and safety risk assessment as part of the audit process.

Key considerations include:

Risk of soil, groundwater, or surface water contamination

Effectiveness of existing spill prevention measures

Fire and explosion hazards

Confined space risks during cleaning or entry

Compliance with HSE and environmental regulations

This stage ensures that the decommissioning strategy protects not only the site, but also the wider environment and the people carrying out the work.

Stage 5: Decommissioning readiness and method selection

Based on the audit findings, we evaluate the most appropriate decommissioning route.

Options may include:

Temporary out-of-service status

Permanent closure in situ

Full tank removal and disposal

The audit identifies which method is suitable and what preparatory works are required, such as emptying, cleaning, gas-freeing, or pipework isolation.

This stage is where audit insight becomes a practical, deliverable plan.

To find out more about the decommissioning process itself, why not check out our in depth articles:

From audit to execution: example landfill leachate tank project

As part of a recent quoted project for a landfill site, OTS was engaged to audit multiple leachate storage tanks ahead of planned infrastructure changes.

The scope identified through the audit included:

Decommissioning of four existing tanks on site

Removal of welded walkways and ladder systems

Decanting and reconfiguration of associated pipework

Lifting and removal of tanks using crane operations

Disposal of tanks via an approved metal recycling facility

Once the site is cleared, the planned next phase involves installation of a new tank system, full pipework reinstatement, and commissioning to return the site to operational status.

This project illustrates how OTS uses audit data to move seamlessly from assessment to safe, structured decommissioning planning.

Get in touch with our team to talk about your decommissioning project.