Fuel storage and management systems for data centres

OTS delivers reliable, future-ready solutions to support your disaster recovery and backup power strategies. Our bespoke fuel storage and management systems are designed specifically for data centres where continuity, control, and resilience are non-negotiable.

Data centres rely on uninterrupted power to keep servers, cooling systems, and critical infrastructure running 24/7.

In the event of a power outage, emergency generators must perform instantly and that means the fuel system behind them must be clean, monitored, and ready. OTS provides bunded fuel tanks and advanced fuel management systems that ensure maximum reliability, fuel quality, and operational uptime.

To find out about our generator base tanks (also known as slab or belly tanks) please click below or get in touch.

From design to installation – a complete turnkey process

Integrated fuel storage solutions tailored for data centre performance.

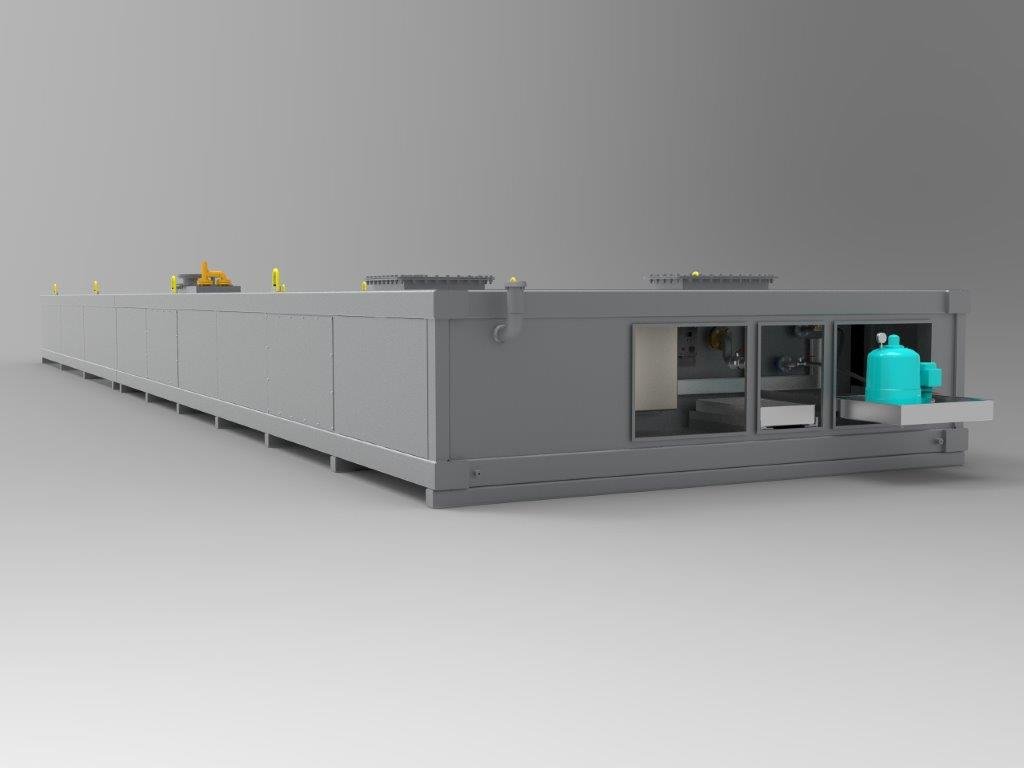

OTS goes beyond standard tank supply. We engineer complete systems that combine robust construction, cutting-edge monitoring, and seamless integration with site infrastructure.

-

Our job is to understand exactly what you need. Our brief and site survey process considers EA compliance, Health & Safety and client concerns to help to guide you to the right fuel storage solution. From the initial brief and site survey, we produce a detailed proposal that includes CAD drawings of our suggested tank solution & images of recommended equipment.

-

OTS Group has invested in additional qualified staff and 3D CAD software to enhance our drawing capabilities, from initial site survey and client briefing, we are able to produce 3D conceptual designs that allow a clear understanding of how the fuelling facility looks and the impact on the available space. Our full “turn-key” solution includes Planning Applications as part of the design & planning process.

-

In addition to the manufacture of bunded steel tanks in our Gloucestershire factory, OTS Group’ full “turn-key” solution ensures that any Civil and Electrical Works required to prep the site are covered.

-

Our specialist installation team work hard to ensure optimal delivery and installation of the tank, pipework and associated equipment, even in some of the most challenging of environments (including first-floor and restricted-headroom sites using skating and winching techniques).

-

At OTS Group, we pride ourselves on service, and we know that a successful delivery isn’t just a ‘set & forget’ affair. That’s why we provide PPM (Planned Preventative Maintenance) programmes to ensure that your data centre can boast 100% uptime. From initial installation through 20+ years of operation, to decommission and replacement when the time comes, we’re here to help.

Best Practices for Fuel Storage

OTS provides full-service project delivery, from initial consultation through to ongoing maintenance.

To ensure safe and efficient fuel storage for data centres, it is important to follow the best practices.

-

Ensure that the storage capacity is sufficient to meet the data centre's power requirements for the desired runtime during an outage. Regularly review and update the capacity plan to accommodate the growth and changing needs of the facility.

-

Implement a robust leak detection system to monitor for any signs of fuel leakage. This may include sensors, alarms, and regular inspections.

-

Periodically inspect and maintain fuel storage tanks to ensure their structural integrity and functionality. This includes checking for corrosion, leaks, or other signs of wear and tear. Find out about Planned Preventative Maintenance.

-

Monitor and maintain the quality of the fuel in storage to prevent contamination or degradation. This may involve regular testing, filtration, and treatment.

-

Adhere to local and national regulations for fuel storage, including requirements for spill containment, tank design, and environmental protection.